- Home

-

Products

- Dust Collecting Units

- Cartridge & Bag Filter

- Baghouse

- Vacuum Unit

- Accessories

- Blower

- Extraction Arm

- Air Lock

- Services

- Industries

- Combustible Dust

- Company

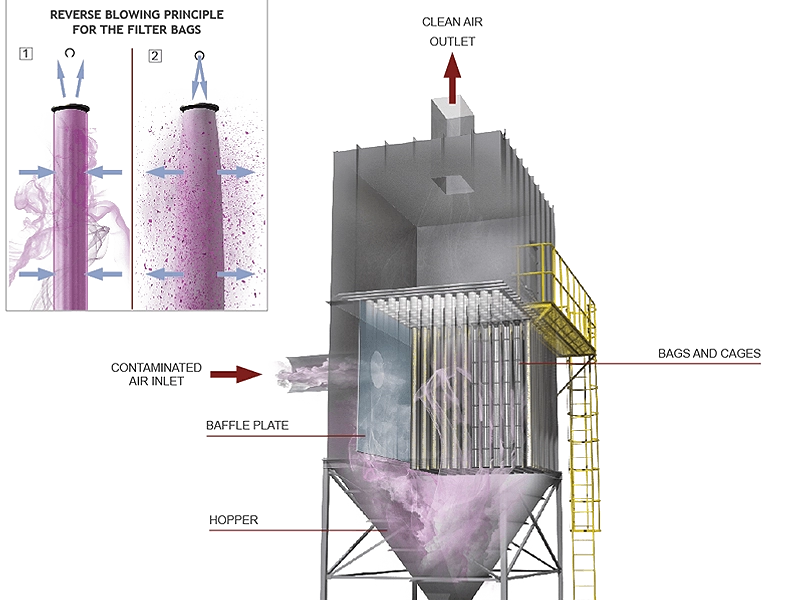

Baghouse dust collectors stand out due to their ability to handle high volumes of dust laden air using a compressed-air self-cleaning system enabling effective reverse blasting through deformation of the filter bags.

The unit filters sub-micron sized particles in continuous operating mode and with a steady loss of differential pressure.

Our line of industrial baghouse dust collectors includes sealed mechanisms as well as doors that provide easy access with very few tools required for maintenance.

High filtration capacity

Models from 50 to 5000 filter bags and up to 500,000m3/h capacity.

Custom engineering

The systems in the H series can be customized based on specific requirements.

Pleated cloth bags

Grad Pleated cloth bag Extended Surface Filters maximize the effective filtration area far beyond conventional filters.

Dust-laden air enters and is directed to the bottom of the dust collector by means of a deflector plate prior to going through the filter bags.

The dust accumulates creating a cake on the outside surface of the bags. At regular intervals, a burst of compressed air is injected into the bags through a parabolic nozzle that creates a shock wave causing the particles to fall to the bottom of the hopper.

The filtered air exits through the venturis into the clean section and is then either expelled outside or recirculated, depending on the application.

Inside-access models: It is possible to replace the bags with just a screwdriver.

Top-access model: The “B”-shaped belt technology requires no tools to replace the bags.

Unlike the shaker models, it is not necessary to shut down this type of dust collector to clean the filters.

The baghouse dust collector is an economical choice because it requires minimal maintenance: only periodic bag replacement is necessary.

substance

shape

particle size

humidity level in the air

load

temperature