- Home

-

Products

- Dust Collecting Units

- Cartridge & Bag Filter

- Baghouse

- Vacuum Unit

- Accessories

- Blower

- Extraction Arm

- Air Lock

- Services

- Industries

- Combustible Dust

- Company

Issues Encountered During Our Interventions...

Humidity

Humidity level control is vital for the production of this application type.

Temperature

Some tasks require precise temperature control throughout product processing.

Dust

Particles generated by this application field accumulate quickly and must be taken care efficiently.

Air Change

To ensure ambient air quality standards, multiple air changes per hour should be performed.

High Energy-Consuming

Processes related to this application field are energy intensive consumers.

Explosion Hazard

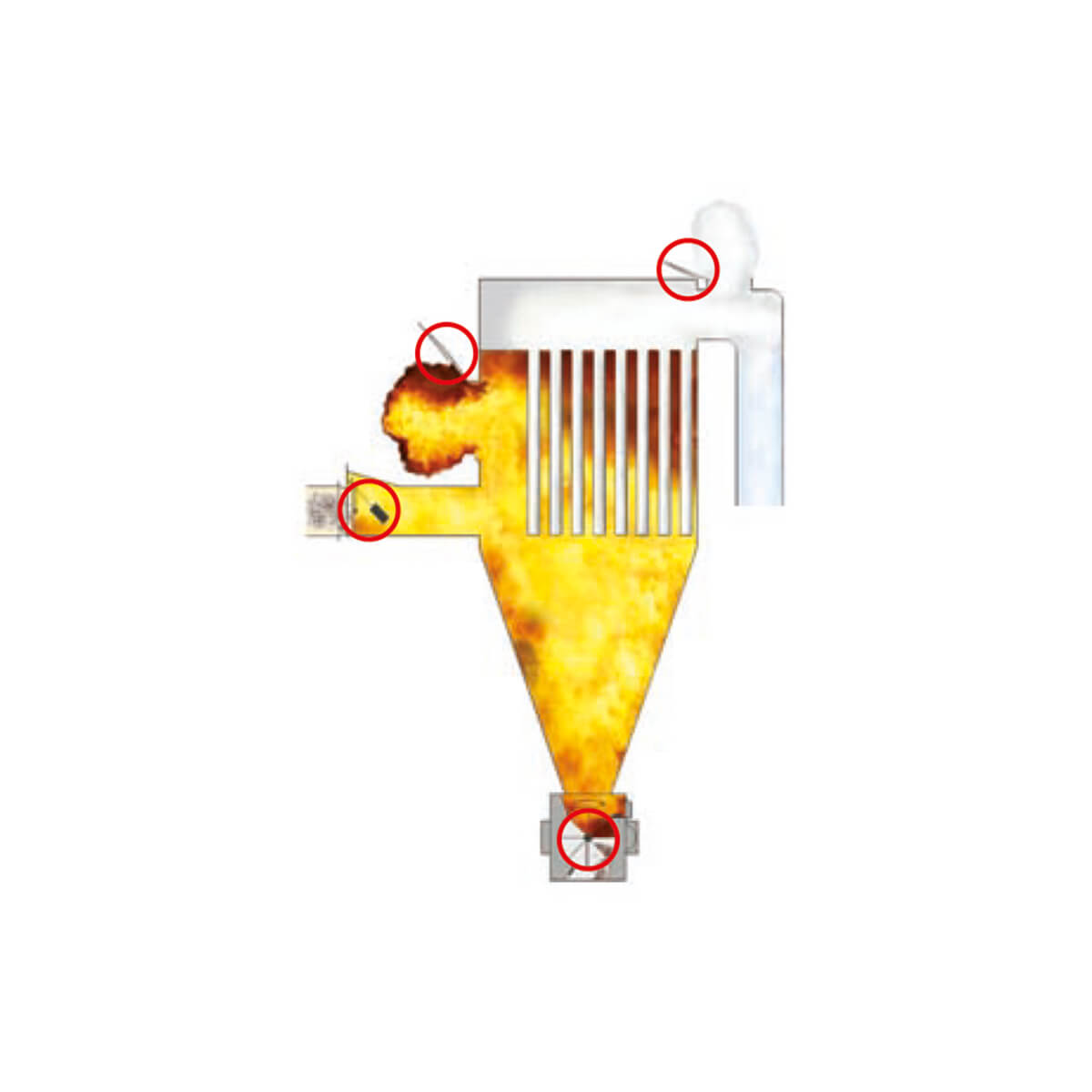

Dust particulate from some materials, for the most part, iscombustible and explosive.

From paper or cardboard strips to clouds of fine volatile particles, you know as well as we do that your processes generate a great deal of dust. What about the hazards associated with your operations and the standards to be met? Examine your facilities and ask yourself:

Is there a risk of deflagration associated with the particles emitted? Since paper and cardboard are organic compounds, they are highly explosive. Do you have the necessary measures in place to contain an explosion and protect your workforce?

What types of dust are produced by your operations? Do their various shapes and fibres impact how they are captured?

You have to manage a large volume of fast-paced production. Do you have dust collection solutions in place to prevent service disruptions due to paper clogging up your processes?

Whether you operate a paper plant, a sorting facility or a printing company, your dust collector is your best ally. In addition to your high production volume issues and the competitiveness of your industry, there is also the health and safety of your workforce. Breathing dusts from fine papers, sanitary tissue products, and cardboard over an extended period poses a health risk to the workers.

If these particles are not controlled through adequate ventilation, they can cause respiratory health problems. For example, your workforce may develop allergies to cellulose dust (main component of paper), asthma and other lung diseases. The Canadian federal regulations and the RSST in Quebec have set occupational exposure limits (OELs) for dust; cellulose has an OEL of 10 mg/m3 of respirable dust. A limit to keep an eye on!

Did you know that cellulose dust is highly explosive? All it takes is a spark, a static discharge, or friction between moving particles to cause a deflagration. You must therefore ensure that you meet the NFPA standards pertaining to the risks of fire and explosion. To comply with them and help you protect your workers, our experts can help you choose a dust collector tailored to your needs.

Your dust collection system depends on your facilities: based on your processes and the size of the company, a number of options are available to you. The larger the work environment, the greater the volume of air to be managed, which influences the choice of dust collector. Your system must also provide good source capture in order to prevent the formation of harmful and explosive dust clouds. It must also be well thought out in order to prevent pieces of paper or cardboard from getting caught in your processes.

We believe that the best dust collector must perfectly meet your needs. It’s also the one that enables you to save money. Our experts can suggest some sustainable options for you that are well thought out to minimize production shutdowns, repairs and energy consumption. Here’s an overview of what we can offer you:

Centralized control system making it possible to optimize operating costs at the process level.

Integrated paper trim capture solutions for the milling and pneumatic conveying systems.

Equipment approved by the NFPA standard for preventing incidents.

A team consisting of engineers and specialists is available to you for breakdowns and preventive maintenance.